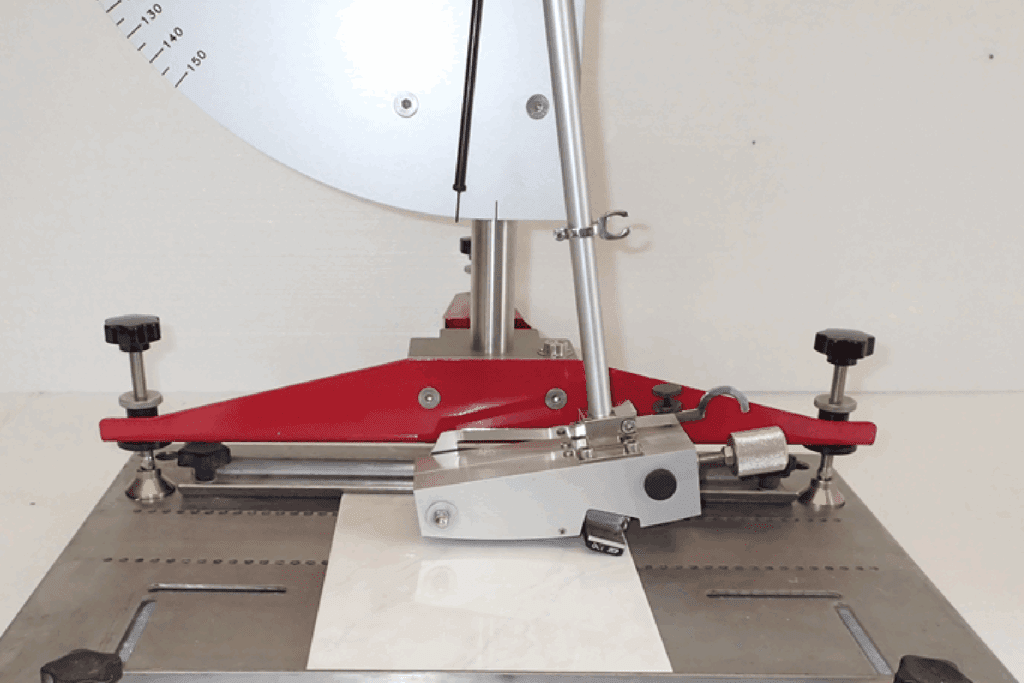

Technical Insight – What Certifiers Look for in a Lab Test Report

Certifiers look for specific details in an AS 4586:2013 slip test report—standard references, NATA traceability, slider type, and finish condition. This guide outlines what’s required and why it matters for compliance and approvals.

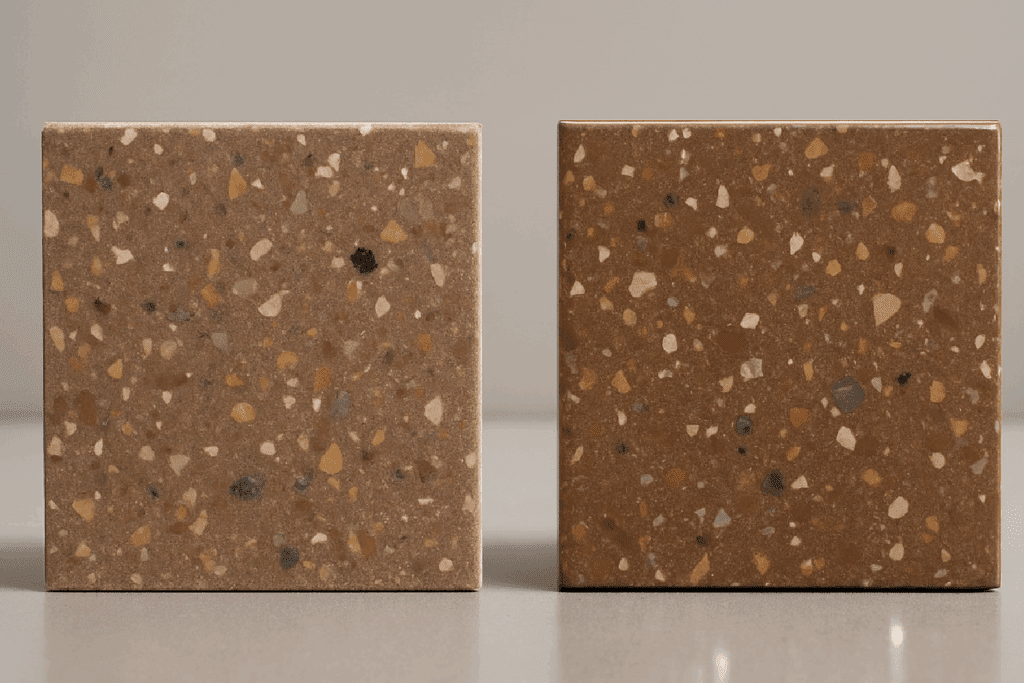

One Product, Two Results: How Coatings Can Change Your P-Rating

Coatings can shift slip resistance by one or more P-ratings. This article explains why surfaces must be tested in their final, treated condition under AS 4586:2013—and what builders and suppliers must do to remain compliant.

AS 4586-2013 Explained: Understanding P and D Ratings

P and D ratings under AS 4586:2013 define how a surface performs under wet or dry conditions. This guide explains the testing methods, classification scales, and how to ensure your product or floor is compliant before installation.

How Often Should You Be Testing? A Risk-Based Guide

Slip resistance isn’t static. Wear, cleaning, and treatment changes can all affect safety. This guide outlines how often you should be testing surfaces under AS 4663:2013—based on risk, site type, and real-world triggers.

Retail Floors: The High-Risk Zones You’re Overlooking

Retail floors often look clean and polished—but that doesn’t mean they’re compliant. Entry tiles, produce aisles, and checkouts are frequent failure zones under AS 4663:2013. This article explains where retail slip risks occur, what HB198:2014 requires, and how to test against real-world conditions.

Can You Fail a Slip Test? Yes — Here’s Why

Surfaces can and do fail slip resistance tests—both in lab and onsite. Whether it’s a new tile rated under AS 4586:2013 or a worn floor checked to AS 4663:2013, results often fall short of what’s needed. This article explains why failure occurs, what happens next, and how to stay compliant.