Should You Test with TRL or 4S Rubber?

Not all slip tests are equal – the slider you choose changes the result. AS 4586–2013 wet pendulum testing uses 4S rubber for general footwear and TRL rubber for barefoot or soft sole zones. A P4 with 4S might drop to P2 with TRL. Choosing the right slider is critical for valid, compliant results.

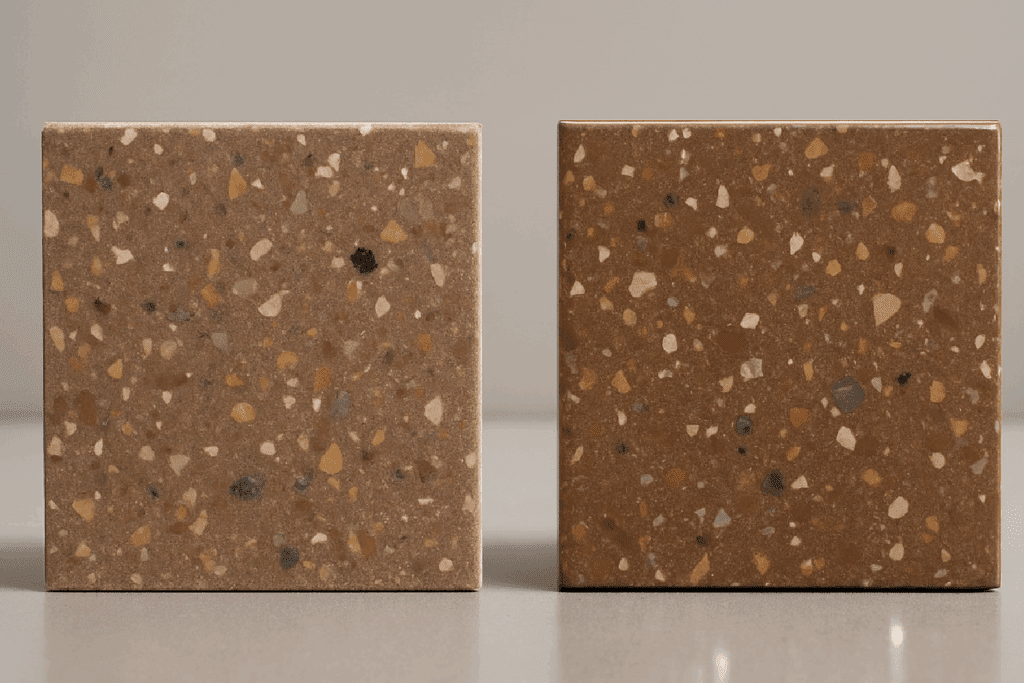

One Product, Two Results: How Coatings Can Change Your P-Rating

Coatings can shift slip resistance by one or more P-ratings. This article explains why surfaces must be tested in their final, treated condition under AS 4586:2013—and what builders and suppliers must do to remain compliant.

How Often Should You Be Testing? A Risk-Based Guide

Slip resistance isn’t static. Wear, cleaning, and treatment changes can all affect safety. This guide outlines how often you should be testing surfaces under AS 4663:2013—based on risk, site type, and real-world triggers.

Retail Floors: The High-Risk Zones You’re Overlooking

Retail floors often look clean and polished—but that doesn’t mean they’re compliant. Entry tiles, produce aisles, and checkouts are frequent failure zones under AS 4663:2013. This article explains where retail slip risks occur, what HB198:2014 requires, and how to test against real-world conditions.

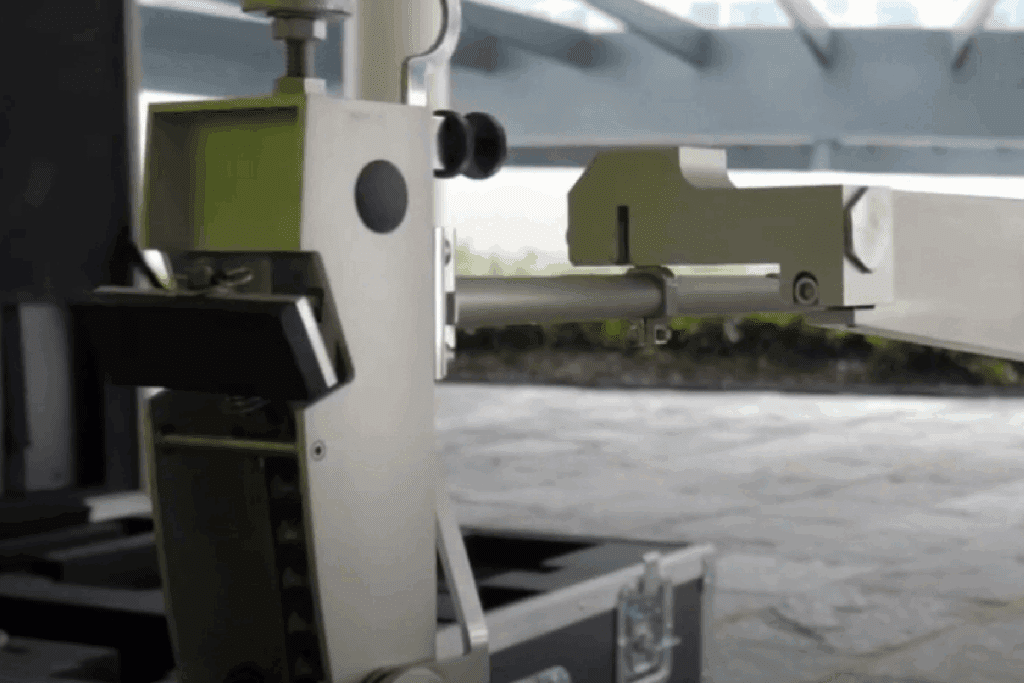

What Actually Happens in a Slip Test Lab?

What really happens behind the scenes of a slip test? We walk you through the lab process – from sample prep to pendulum results and certification.

Shiny Doesn’t Equal Safe: Why You Still Need a Slip Test

A polished floor may look premium—but it tells you nothing about slip resistance. Learn why visual checks aren’t enough, and why certified slip testing matters.

Aged Care – Hygiene vs Safety

Aged care facilities prioritise cleanliness—but some hygiene methods increase slip risk. This article explores how to maintain both safety and sanitation.

“It Looked Fine” : When Visual Safety Isn’t Enough

Looks can deceive. Learn why visual inspections aren’t reliable for slip risk—and why certified slip testing is essential for workplace safety and compliance.