When Should a Product Be Re-Tested? The Question Manufacturers Get Wrong

Learn when flooring products should be re-tested for slip resistance and why one result rarely covers a full product range.

Learn when flooring products should be re-tested for slip resistance and why one result rarely covers a full product range.

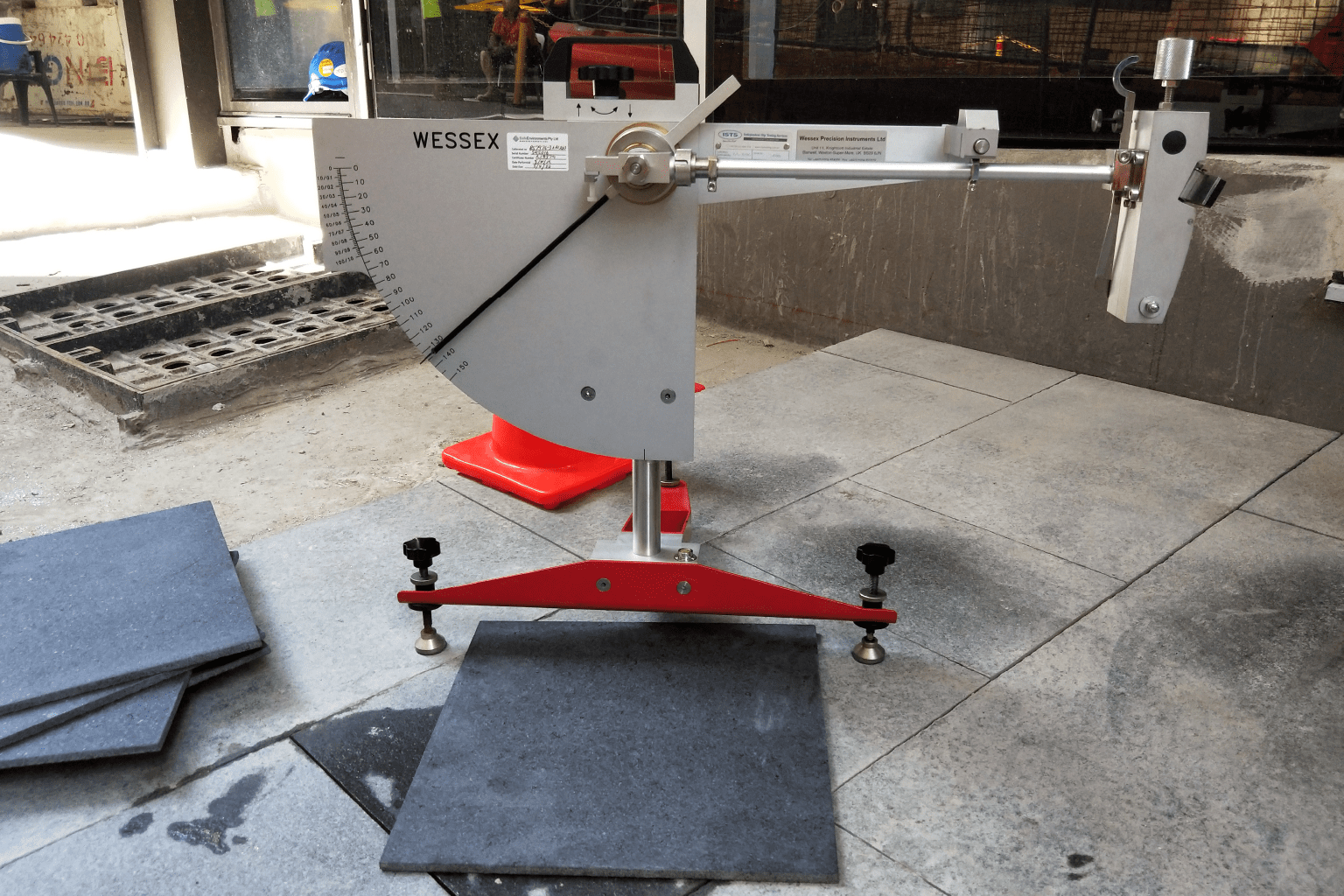

Colour, grit and finish change slip resistance. Learn why P-ratings vary across tile ranges and coatings

Slip resistance varies across colours and finishes. Learn why one AS 4586 test cannot certify an entire product line.

Curing is one of the most overlooked factors in slip resistance testing. This article explains how premature testing can understate performance, invalidate AS 4586 results,

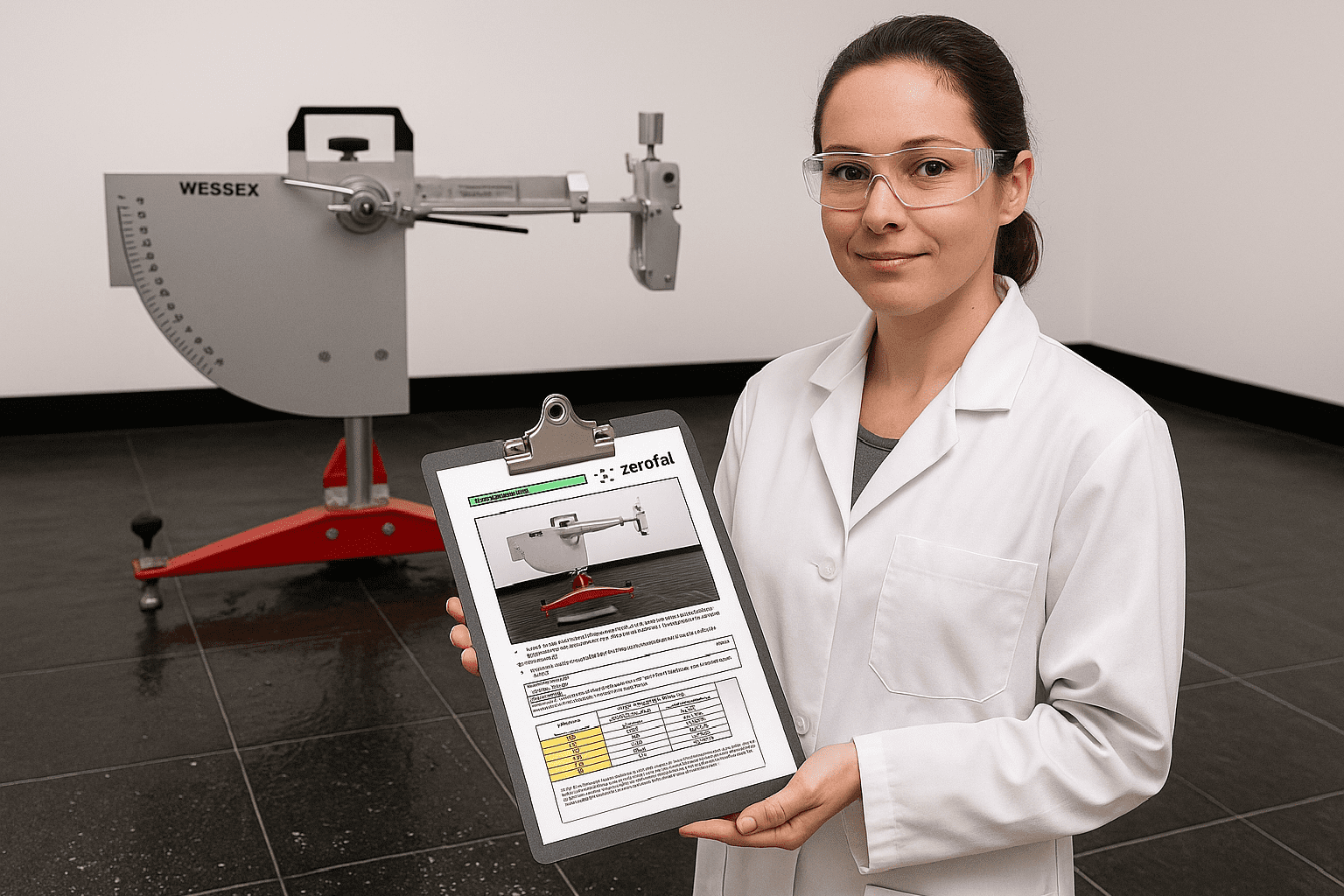

Accurate slip resistance results start before the test begins. This guide outlines how to prepare your samples for AS 4586 testing – covering size, cleaning,

AS 4586:2013 classifies dry-use surfaces as D0 or D1. Learn why the cut-off matters and why even one low result can mean a fail.

Borderline slip resistance results may pass one interpretation but fail another. Learn how AS 4586:2013, AS 4663:2013 and HB198:2014 apply in practice.

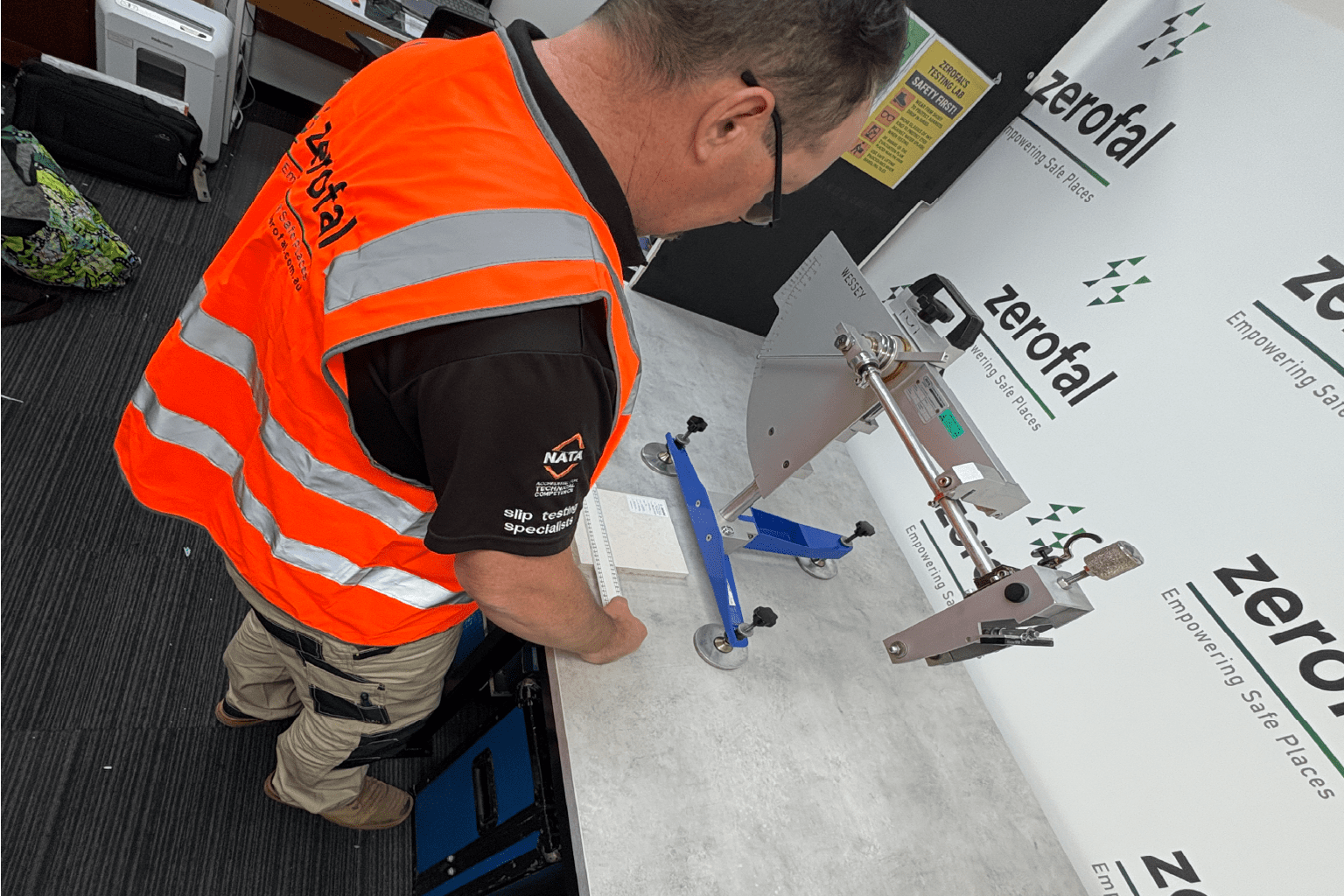

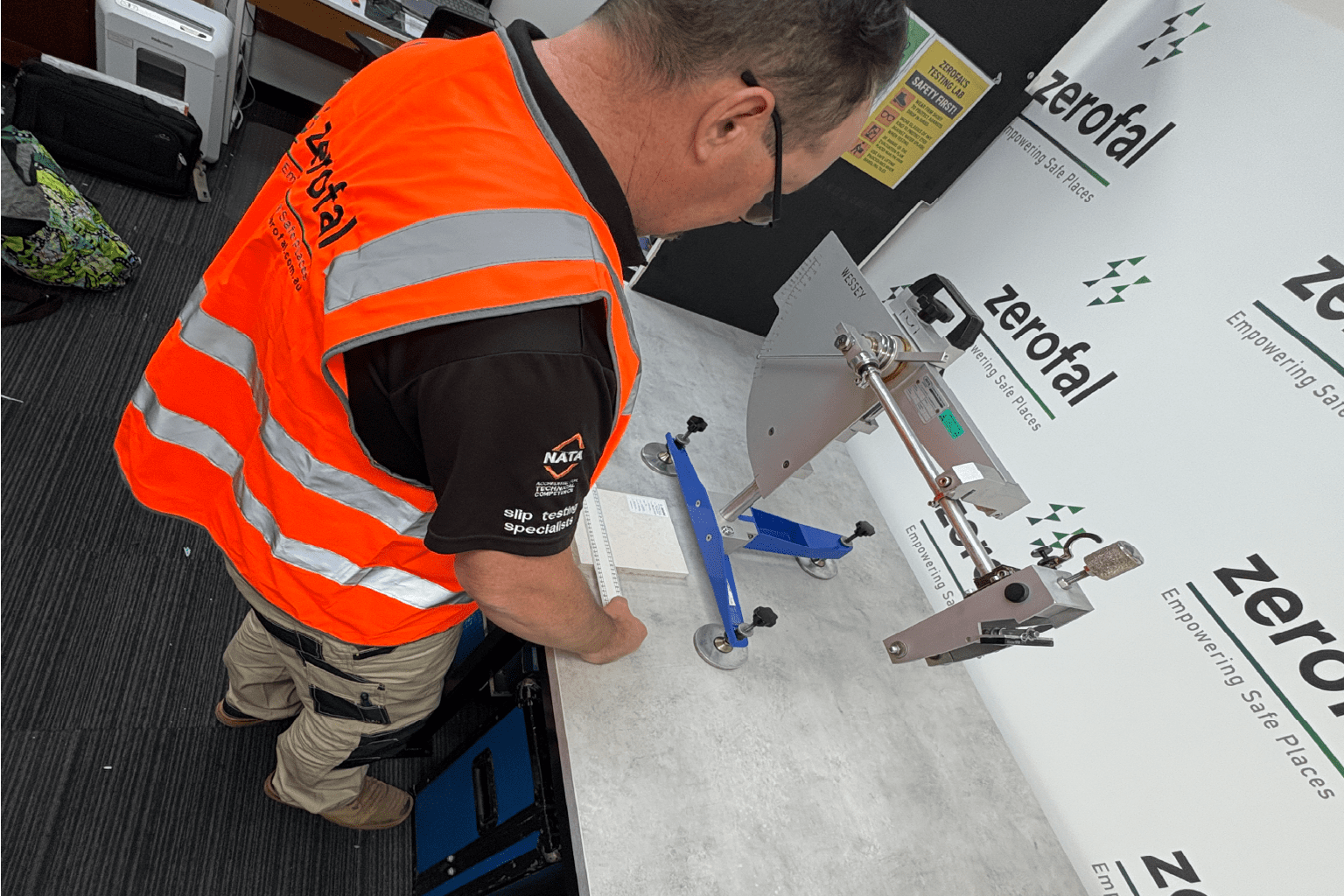

What happens inside a slip testing lab? Follow the process from tile submission to AS 4586:2013 certification in Zerofal’s Sydney lab.

Not all slip tests are equal – the slider you choose changes the result. AS 4586–2013 wet pendulum testing uses 4S rubber for general footwear

Sample quality drives valid AS 4586–2013 results. Send a minimum 200 × 200 mm tile per finish, clearly labeled and packed flat on a rigid

Join the Zerofal newsletter for actionable insights on slip testing, compliance updates, and smart prevention strategies. No spam – just practical safety advice.