Designing for Safety: Slip Resistance as WHS Architecture

Why Slip Resistance Must Be Designed In

Slips, trips and falls cause over 22% of serious workplace injuries in Australia, costing tens of thousands per claim. Many incidents occur on surfaces that look safe but test below standard. Slip resistance must be built into workplace design from the start – not left to chance at handover.

Slips, trips and falls remain one of the top three causes of serious injury in Australian workplaces, responsible for more than 22% of serious workers’ compensation claims each year. Each claim typically costs tens of thousands of dollars in medical, legal, and insurance expenses, alongside reputational damage for the organisation involved.

Too often, flooring safety is treated as an afterthought – a box to be ticked at the end of a project or in response to an incident. In practice, slip resistance should be treated as a design parameter from the outset, just as critical as fire safety, load bearing, or accessibility.

The Risk of Minimum Compliance

A recent commercial site in Sydney’s CBD highlights the problem. External entry surfaces were installed with high-quality stone and maintained to a good standard. On visual inspection, they looked safe. But when tested under AS 4663:2013, wet pendulum results dropped to P2 classification in some areas – below the requirements in HB198:2014 for external ramps.

The cause was a combination of slope, contamination, and surface variation. To anyone walking in, the risk wasn’t visible – but it was measurable and real.

What the Standards Require

Slip resistance in Australia is defined by:

- AS 4586:2013 – lab or onsite testing for new surfaces

- AS 4663:2013 – in-situ testing of existing surfaces

- HB198:2014 – guidance on where different P or D ratings apply

Examples:

- External ramps steeper than 1:14 require P5.

- Commercial kitchens require P5.

- Retail entries and hotel lobbies require P3 or higher, depending on exposure to wet weather.

Designing for Safety, Not Retrofits

To integrate slip resistance at the design stage:

- Request AS 4586:2013 test reports before specifying flooring.

- Match surface classification to its location.

- Factor in slope, drainage, coatings, and finishes.

- Verify through on-site testing before handover.

Benefits of Building Safety In

- Reduced incidents and claims

- Defensible compliance with NATA-traceable reports

- Insurance leverage with lower premiums

- Cost control by avoiding retrofits

- Reputation protection through proactive WHS

Zerofal’s Role

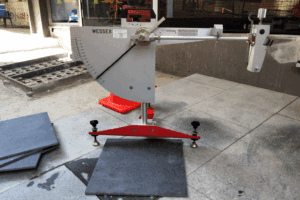

Zerofal provides AS 4586:2013 laboratory testing and AS 4663:2013 in-situ testing using calibrated pendulum skid testers and Tortus 3 dry friction testers. Reports are NATA-traceable and formatted for compliance documentation.

Design for safety, not liability

Book accredited slip resistance testing with Zerofal today.

Explore more

Colour, Grit and Surface Finish: How Subtle Differences Change Slip Ratings (AS 4586:2013)

Colour, grit and finish change slip resistance. Learn why P-ratings vary across tile ranges and coatings

Why One Slip Test Isn’t Enough for Product Lines (AS 4586:2013)

Slip resistance varies across colours and finishes. Learn why one AS 4586 test cannot certify an entire product line.

Industrial Slip Resistance: Dust, Boots & Coating Drift (AS 4663:2013)

: Industrial floors change fast. Learn how dust, coatings and machinery reduce slip resistance and why AS 4663 onsite testing is essential.